|

||||

Flexible polyurethane foam is one of the most versatile synthetic open cell materials.

Sub-divided into the two big families of polyether and polyesther, and available as a raw material in blocks or rolls, there are hundreds of versions, which differ for colour, physical-mechanical characteristics and flame resistance.

Applications are therefore a lot different, depending on the chosen version:

- pads for upholstery and packing

- soft gaskets

- filtration

- sound absorption

- sealing

- mattresses and orthopaedic / medical items

We herebelow show a detail of some variations of polyurethane foam we usually deal with.

Polyether and polyesther foams in colour and density of choice, from 18 to 120 Kg/ cu.m.

Resiliency, cells dimension, water absorption differ depending on the version.

We can suggest materials which differ for flame resistancy, compliant to FMVSS 302 and UL 94 standards.

Available in rolls, sheets, contoured or die-cut parts.

Surface can be smooth, convoluted, pyramidal, with open or semi-closed cells, or laminated to plastic or metallic film, or to fabric.

Reticolated foams of fully open celled polyurethane, polyether or polyether resin, black or blue colour.

They’re suitable for the filtration of air, water, oils.

The different porosities (10-20-30-45-60-80-90 PPI ) enable to supply the most suitable material for any filtration need.

They show excellent water resistance, whereas they differentiate as to the flame behaviour: one particular version, impregnated by special substances, reach CLASSE 1 of flame retardancy (maximum thickness available is 20 mm ).

Viscoelastic polyurethane foam PUR 300 is characterized by a slow return to its original thickness after a compression set.

This grey , high density ( approx. 90 Kg/cu.m. ) material has been designed to be employed in the automotive gaskets field and as a sound absorber ( it is a very good alternative to heavier materials, such as rebounded rubbers, bituminous sheets or impregnated foams ).

Its ability to comfortably contour the shape of the body whom is pressing it, and to sustain it, makes it an ideal material for orthopaedic mattresses and other medical applications.

Differently from fully open celled polyurethane foams, some versions show a large percentage of closed cells. This makes that, if you compress them from 30 to 50 per cent of their original thickness according to the version, the air that at the beginning filled the cells is pushed out, and the gasket remains made just of a material which is non-permeable to air, water, dust, etc.

The advantages of adopting these flexible polyurethane foams for sealing instead of other closed cells materials are many:

- lower cost

- lower weight, though ensuring the same performance ( typical density is 25-30 kg/ cu.m., against 100-120 of foam rubber or PVC foam )

- low outgassing

- they are ecological, because they are recyclable ( by means of granulation ).

The flexible polyurethane foams of the FELTFOAM range are manufactured to meet specific needs of the client.

From standard flexible foams, we can obtain any grade of density, resiliency, tensile strenght, elongation at break, not normally available in the market.

In particular, some versions of FELTFOAM show an open but extremely dense cell structure, which makes them ideal for detaining, and subsequently slow releasing, of liquids such as ink, oils etc.

They are therefore used as ink-pads for rubber stamps or printers, as gaskets in the motor compartment of vehicles or machineries, and so on.

Long work life, non putrefiability, flame resistance and low cost make FELFOAM a valid alternative to woollen or synthetic felt.

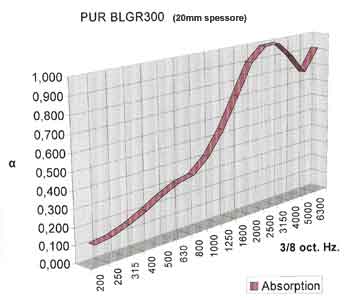

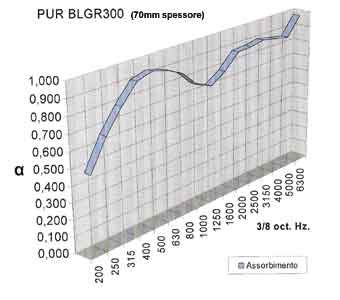

Flexible polyurethane foam is, in general, a good sound absorber. We can suggest high performance versions, designed just to this purpose, showing also a good flame resistance ( standards FMVSS 302 and UL 94 ).

In several applications ( building, mass transit etc ) is, in fact, extremely important that in case of contact with the flames these materials won’t burn and won’t let incandescent drops fall down.

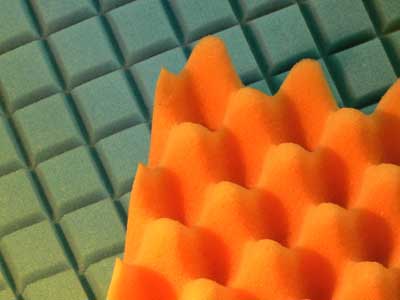

The sound-absorbing properties of flexible polyurethane foam can be enhanced by modeling the surface of the sheets of the original material in order to obtain a convoluted or pyramidal effect, increasing in this way the surface that entraps noise.

For each material, the thicknesses of the smooth base and of the ashlar, or pyramid, are the client’s choice.

Product is sold in sheets, rolls or pieces cut to size.

Flexible polyurethane foam is a recyclable material.

The wastes from the manufacturing process are granulated and then permanently rebounded, obtaining a flexible polyurethane foam having a peculiar micro-spotted, multi-coloured look

This material, particularly suitable for packings and pads, is available in several densities, from 60 to 300 kg/cu.m.

Supplied as: sheets, rolls, shaped parts, die-cut gaskets.

- for applications in the electronics ( as components or anti-shock packings ): conductive or anti-static flexible polyurethane foams

- resin- or bitumen-impregnated, for applications in the building industry ( interstitial joints, sealing of windows, ducts etc )

- silicone impregnated: for filters withstanding high temperatures ( see section filters ).

C.F. Italia s.r.l. via Cavallo, 18 - 10078 Venaria R. (TO) - Tel: 011.4593506 Fax: 011.4593459 - P.Iva 04577710017

Home |

Company |

Products |

Quality |

Contacts |

Privacy |

Italian

![]()